Types of PE Film: Features and Applications - Grandwin

What is PE film?

The cast extrusion process produces PE film with uniform thickness, excellent transparency, and Glossiness. The blow molding process produces low-cost films with better barrier properties and machine strength, which are more widely used.

Types of PE film

There are many PE film types. It can be divided by density and molecular structure. It can also be categorized by function.

Density and molecular structure:

Density and molecular structure have a great influence on film properties and functions. Understanding this will allow you to better select the right type of film.

Low-Density Polyethylene (LDPE): It has a highly branched molecular structure; It has a high degree of short and long-chain branching. It has excellent flexibility, elongation, and impact resistance. It is suitable for various packaging applications. Its density is usually between 0.913 and 0.922 g/cm³. LDPE film is mainly used in food preservation bags and cling film scenarios. Its moisture resistance is good for preventing food spoilage. Although LDPE film is recyclable, the recycling process is still difficult.PE Protective Film for Plastic SheetsSelf Adhesive Paper For Plastic

Linear Low-Density Polyethylene (LLDPE): The molecular structure of LLDPE film is linearly arranged and has a higher number of short branched chains. LDPE film has excellent tensile strength, puncture resistance, and durability. Its density ranges from 0.913 to 0.928 g/cm³. LLDPE film is strong and holds and protects products well during storage and transportation. LLDPE film also has superior tear resistance and electrical insulation.PE Protective Film for Plastic Sheets,PE Self-Adhesive Protective Film

High-Density Polyethylene (HDPE): HDPE film has a linear structure. There are fewer branching chains, and most linear molecules are stacked in an orderly fashion. The density is higher. 0.940 to 0.962 g/cm³. HDPE films are mainly used in heavy-duty applications. HDPE is also used for daily necessities, containers in industrial scenarios, tubing, and making films. Self Adhesive Paper For Plastic,PE Self-Adhesive Protective FilmPackaging tapes, ropes, cables, etc.

Functionality:

In order to meet different usage scenarios, PE films can also be categorized by function.Including protective film, Easy Peel Films, and anti-static film.

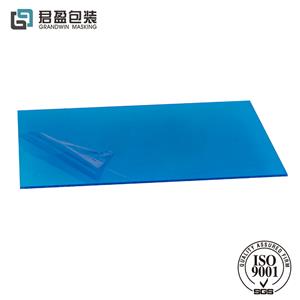

Protective film: PE protective film has excellent tear resistance. It is used to protect the product surface from damage during transportation and handling. Free from scratches and dust.Mainly used for industrial equipment parts and automobile parts. Prevent damage during handling and transportation. Also used to protect electronic equipment.

Easy Peel Films: Easy Peel Films are made with a special coating that makes it easier to peel off the film. Easy Peel Films are mainly used in plastic sheet. It is very convenient and can give consumers a good experience.

Anti-static film: It can reduce or eliminate static electricity. It is very important for those electronic components that are sensitive to static electricity. It protects them from damage. Antistatic film is also used in powdered food packaging. Antistatic can prevent food from clumping and ensure the integrity of the food. It can also be used for medical device packaging. Prevents static electricity from damaging medical equipment.

FAQ

Is PE Film Safe for Food Packaging?

PE films can usually come into direct contact with plastic sheet. However, in order to avoid the release of chemicals into the plastic sheet. It must be certified, tested, and examined before packaging. Polyethylene is available in good grade . Be careful when choosing. Although polyethylene is heat-resistant.But prolonged exposure to high temperatures. It may lead to the release of chemicals. Guidelines for use need to be followed.