Grandwin’s New PC/PMMA Protective Film Enters Mass Shipment

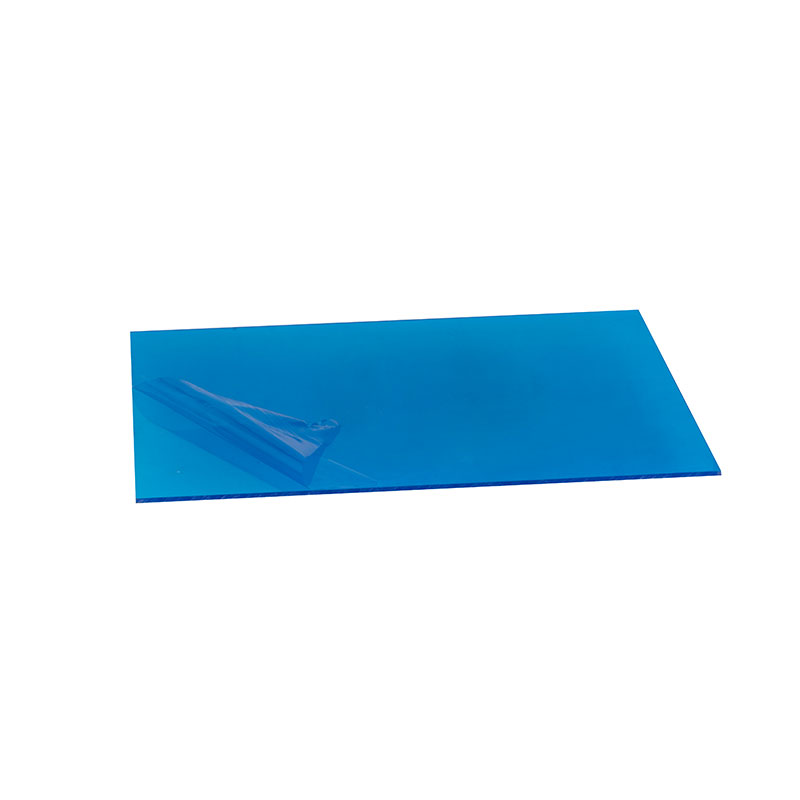

Recently, Grandwin Packaging Technology Co., Ltd. (Shunde, Guangdong), a world-renowned self adhesive film supplier and manufacturers, announced the grand launch of its independently developed new high-performance PE Protective Film for Plastic Sheets and Protective Film for Acrylic Sheet, which have completed the first batch of mass shipment. Relying on innovative coating technology and environmentally friendly substrate formulas, this series of products has achieved comprehensive upgrades in weather resistance and adaptability on the basis of core advantages such as easy tearing, no adhesive peeling, no residue, and durable protection. It can accurately meet the high-end protection needs of PC/PMMA sheets in various fields such as electronics, automobiles, and construction, once again demonstrating Grandwin's technical strength and industry insight as a professionalself adhesive film supplier and manufacturers.With the rapid development of emerging industries such as 5G communication and intelligent automobiles, PC sheets and PMMA sheets (acrylic sheets) have been increasingly widely used in scenarios such as electronic device casings, automotive lighting systems, and building lighting curtain walls due to their advantages of light transmittance, lightweight, and mechanical properties. However, such precision sheets are prone to surface scratches, stain adhesion, and other problems during processing and cutting, warehousing and transportation, and terminal assembly, putting forward more stringent requirements for the performance of protective films. As a self adhesive film supplier and manufacturers with years of experience in the surface protection field, Grandwin keenly captured changes in industry demand, set up a special R&D team to carry out technical research, and finally launched this new type of protective film product suitable for multiple scenarios.

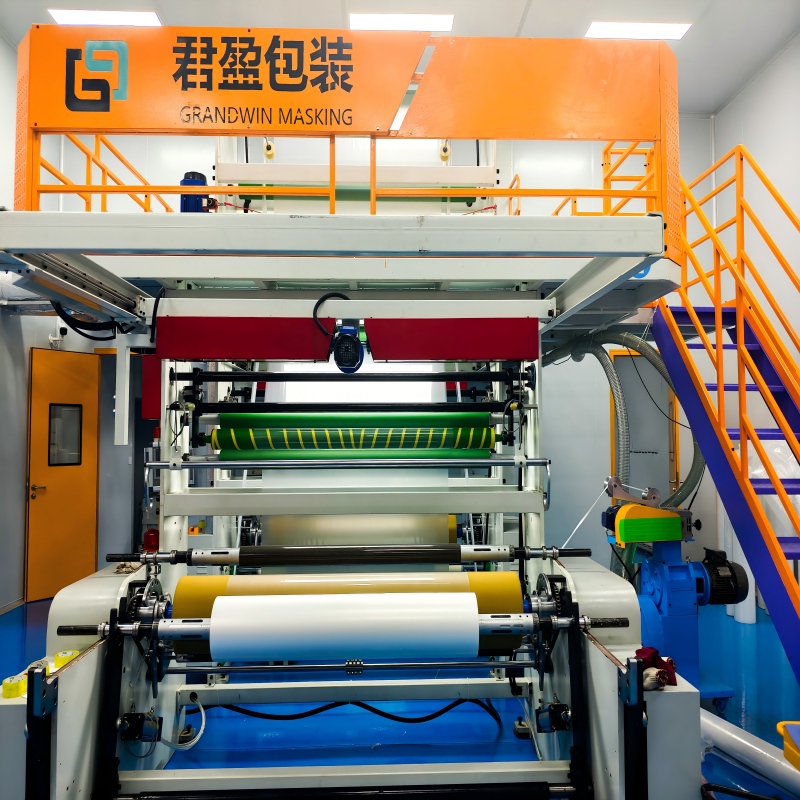

The core highlights of the newly launchedPE Protective Film for Plastic Sheets and Protective Film for Acrylic Sheet lie in the adoption of polydopamine modified composite coating technology and high-quality LDPE Release Liner, achieving three major technological breakthroughs. Firstly, by optimizing the release performance of LDPE Release Linerand the composite process of the substrate, the tearing resistance of the product is reduced by 30%, enabling easy one-handed peeling even in low-temperature environments, which greatly improves the production efficiency of downstream enterprises. Secondly, environmentally friendly cross-linked acrylate adhesives are selected, combined with high-precision coating technology, to ensure that the protective film adheres closely to the sheet without generating bubbles. After long-term use in a wide temperature range of -30℃ to 90℃, it still achieves no adhesive peeling and no residue when removed, perfectly avoiding the risk of sheet scrapping caused by adhesive stain pollution of traditional protective films. Thirdly, the composite coating endows the product with excellent scratch resistance and weather resistance. According to authoritative testing, its surface hardness reaches 4H level, which can effectively resist external damage such as gravel impact and tool friction. Meanwhile, it has excellent UV aging resistance, maintaining stable protection performance for more than 12 months under outdoor exposure conditions. As a powerful self adhesive film supplier and manufacturers, Grandwin has established a full-process quality control system in the production link. The entire production process of this series of products is completed in a Class 1000 clean room. From raw material selection, LDPE Release Liner pretreatment to finished product testing, each process is accurately controlled by intelligent equipment to ensure the performance consistency between product batches. At the same time, Grandwin also provides personalized customization services, which can adjust the thickness, viscosity and width specifications of the protective film according to customer needs. It can support the customization of PE Protective Film for Plastic Sheets and Protective Film for Acrylic Sheet with a maximum width of 2200mm, and can also realize the precise printing of brand logos through two-color printing technology, fully meeting the differentiated needs of different customers.

According to Grandwin's Marketing Director, the first batch of newly launched protective film products that have been shipped in bulk have been successfully delivered to a number of domestic leading electronic terminal manufacturers and auto parts enterprises, covering multiple application scenarios such as PC sheet protection for intelligent terminal casings and PMMA sheet protection for automotive light guide plates. "From customer feedback, the easy tearing, residue-free characteristics and durable protection effect of the product are fully in line with expectations, and some customers have reached long-term cooperation intentions," the director said. As a professional self adhesive film supplier and manufacturers, Grandwin will take the launch of this new product as an opportunity to continuously increase R&D investment in new materials and new processes, further enrich the product matrix of PE Protective Film for Plastic Sheets, Protective Film for Acrylic Sheet and LDPE Release Liner, and provide more competitive surface protection solutions for global customers.

Industry insiders pointed out that the launch and mass shipment of Grandwin's new PC/PMMA sheet protective film not only fills some technical gaps in the field of high-end precision sheet protection, but also provides a useful reference for the technological upgrading of the surface protection industry. In the future, with the continuous deepening of Grandwin's global layout, its brand influence as a self adhesive film supplier and manufacturers will be further enhanced, injecting more impetus into the high-quality development of the global precision manufacturing industry.