High-adhesion zinc anode protective film with metal-ion-doped conductive polymer-coated carbon nanotubes for zinc ion batteries

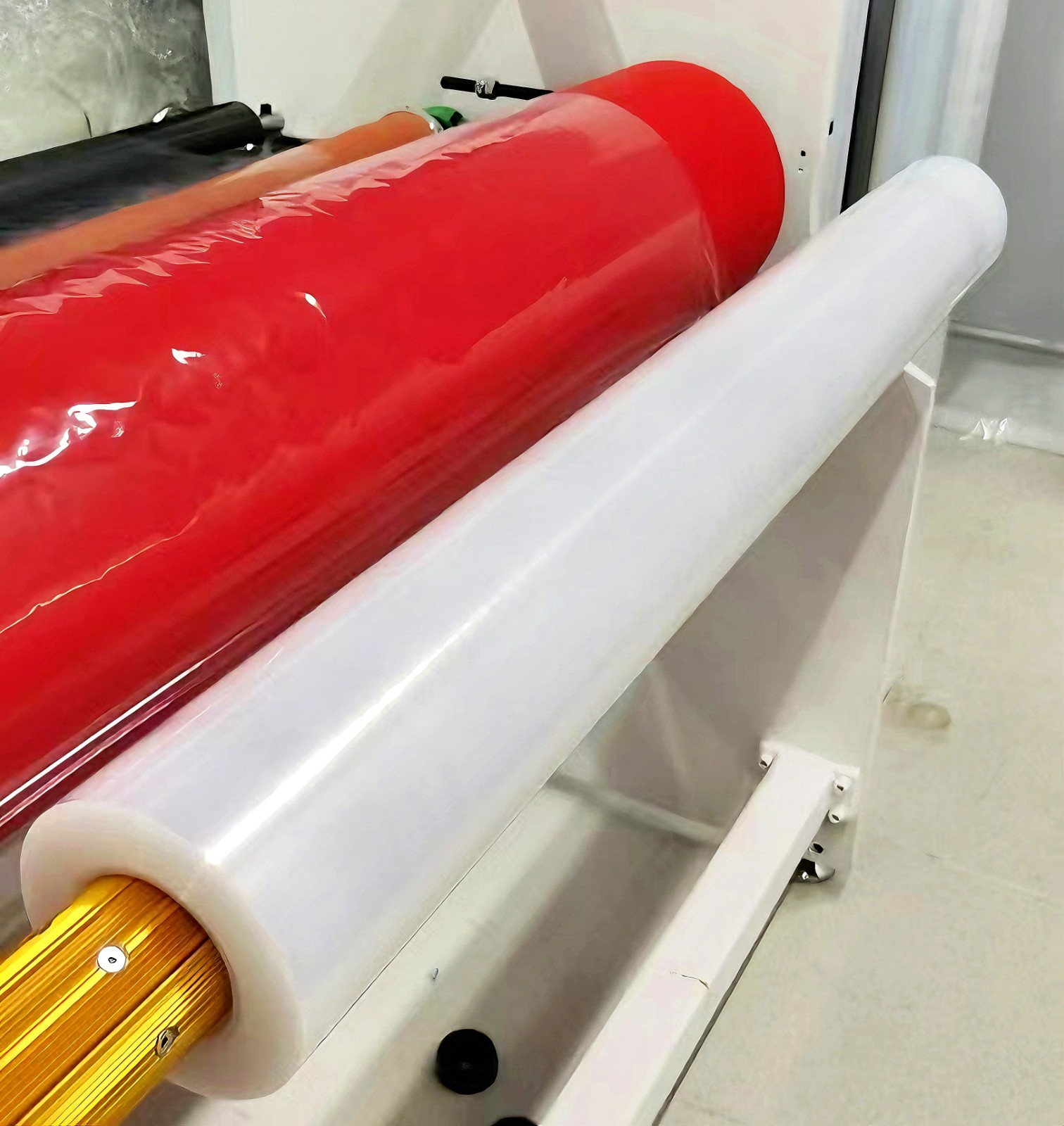

Recently, Grandwin, a well-known R&D and manufacturing enterprise specializing in protective films, officially released its new-generation PE Self-Adhesive Protective Film. With its outstanding adhesive stability, weather resistance, and wide adaptability, this product has quickly become the focus of attention in industries such as electronics, building materials, and furniture. This new launch not only further improves Grandwin’s PE protective film product portfolio but also redefines the application standards of Self adhesive protective film in the field of product surface protection through innovative technologies.

As a core product series of Grandwin that has been deeply engaged in the protective film field for many years, PE protective film has always adhered to the core design concept of "efficient protection and convenient use". The newly launched PE Self-Adhesive Protective Film adopts high-purity polyethylene resin in raw material selection, combined with advanced gluing technology. This ensures that the protective film can not only adhere tightly to the product surface during application but also leave no residual adhesive when peeled off later, effectively solving the industry pain points of traditional Self adhesive protective film such as "insufficient adhesion leading to easy falling off" and "difficulty in cleaning residual adhesive". Whether it is smooth glass panels, metal casings, or furniture boards with complex textures, this PE Self-Adhesive Protective Film can achieve precise adaptation, providing comprehensive surface protection for products during production, transportation, storage, and installation, and avoiding damage to product appearance and performance caused by scratches, stains, oxidation, and other issues.

It is worth noting that in the R&D of this new product, Grandwin has specially optimized the weather resistance of the PE protective film. After multiple extreme environment tests, the new-generation PE Self-Adhesive Protective Film can still maintain stable physical properties within the temperature range of -20℃ to 60℃, with an adhesive attenuation rate of less than 5%, fully meeting the usage needs in different regions and seasons. At the same time, in response to the high requirements for the light transmittance of protective films in the electronics industry, this product also has a light transmittance of more than 90%, which does not affect the appearance inspection of products after application, making it an ideal protective choice in the production process of precision electronic products such as mobile phones, computers, and smart devices.

In addition to the PE Self-Adhesive Protective Film, Grandwin’s Pe Protection Film series also includes various specifications such as low-adhesion, medium-adhesion, and high-adhesion, which can provide customized solutions according to customers’ different product materials and protection needs. Furthermore, the Release Film produced by the company as a supporting product forms a perfect match with the PE protective film. During the production, storage, and transportation of the protective film, it effectively prevents adhesion between protective films, ensuring the integrity of the products when they leave the factory. According to the person in charge of Grandwin’s products, currently, the company’s PE protective film and Release Film products have passed the ISO 9001 quality system certification and are exported to more than 20 countries and regions around the world, serving hundreds of well-known Chinese and foreign enterprises.

In the building materials industry, Grandwin’s Self adhesive protective film also performs brilliantly. Aiming at the problem of surface damage that easily occurs to building materials such as aluminum alloy doors and windows, stainless steel plates, and ceramic tiles during transportation and installation, the company’s PE protective film can form a tough protective barrier to resist external impact and friction. At the same time, its excellent UV resistance can prevent building materials from fading and aging due to long-term exposure to sunlight. The purchasing director of a large building materials enterprise said: "We have cooperated with Grandwin’s PE Self-Adhesive Protective Film for many years. The stability and protective effect of the product have always been reliable, which has effectively reduced the product loss rate of our enterprise and helped the enterprise save a lot of costs."

As consumers’ requirements for product appearance quality continue to increase, the market demand for Self adhesive protective film keeps growing. Relying on its keen insight into industry trends and technological innovation capabilities, Grandwin continues to promote the upgrading of PE protective film products. The launch of this new-generation PE Self-Adhesive Protective Film not only reflects Grandwin’s technological strength but also will provide efficient and reliable surface protection solutions for more industries. In the future, Grandwin will continue to increase R&D investment, explore the application of PE protective film in more emerging fields, and create greater value for global customers.